Für die Funktion dieser Website werden Cookies verwendet.

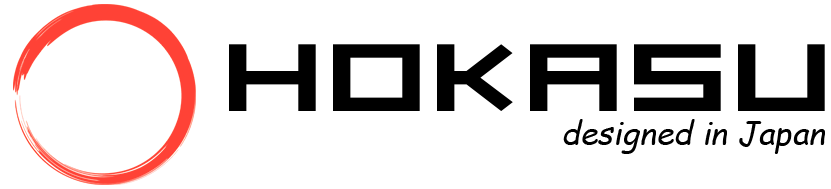

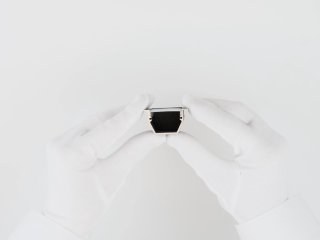

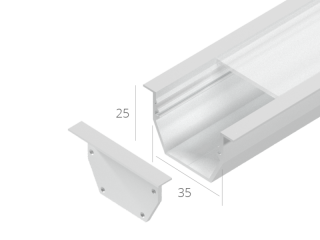

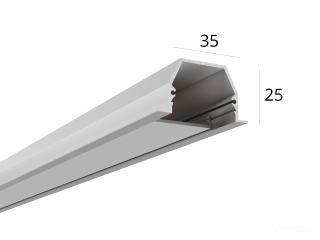

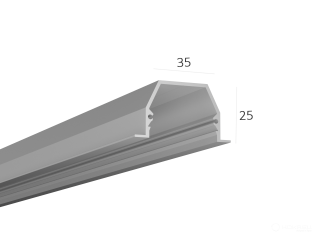

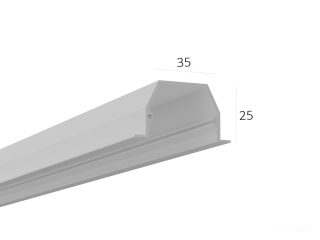

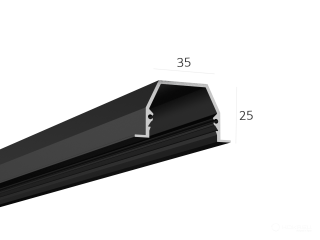

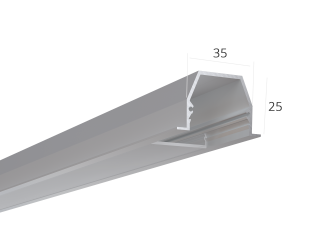

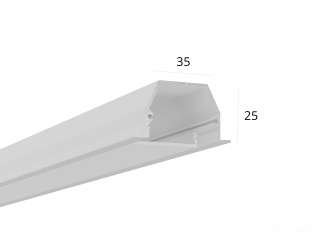

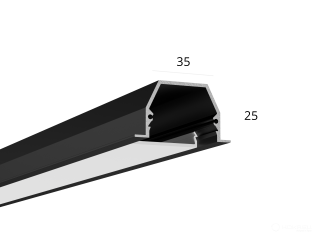

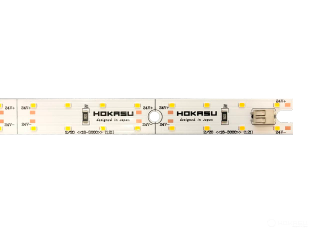

35-25 in_1

35-25 in

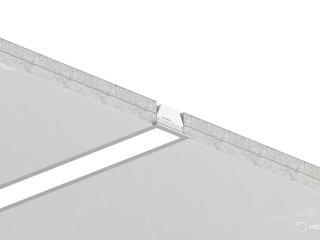

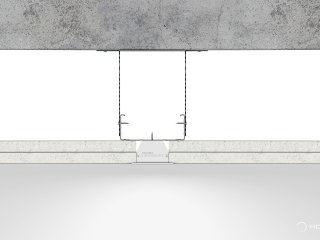

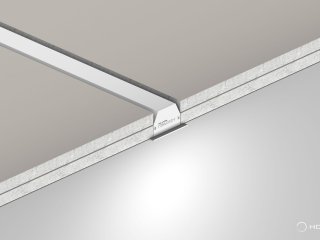

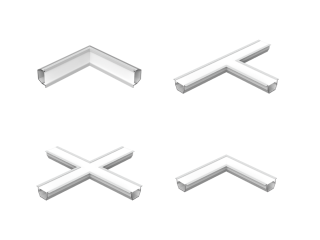

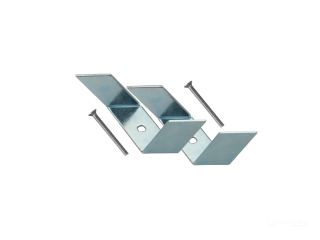

Anodized/painted aluminum profile for recessed linear luminaires.

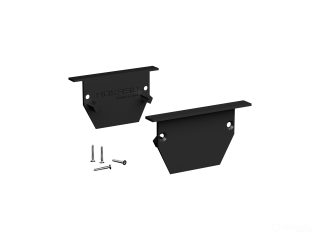

Packages

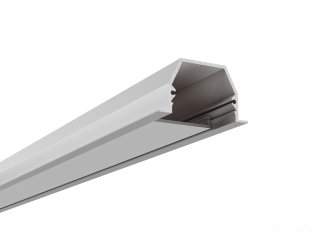

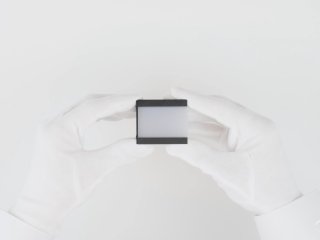

— to choose from: with or without a screen

HOKASU branded plugs sold separately.

Dimensions: 35(45)x25mm

Profile weight: 0.360kg/m

Design

Profile is made of aluminum alloy 6063 (AD31) and is hardened in the press to achieve the highest-strength condition T6. The surface is machined on an Italian anodizing line «Qualanod» – The lamp body is highly resistant to scratches and corrosion.

Diffuser - made in Europe

A modern solution for the linear luminaire - diffusers with patented HGC, HPC and HHC technologies.

The HOKASU Glare Control (HGC) technology was developed specifically for commercial environments. Based on the technology, we produce transparent and prismatic diffusers with high light transmission and a pleasant geometric lighting effect. HGC diffusers are UGR (Unified Glare Rating) compliant and allow you to increase the lighting efficiency of commercial spaces up to 90%.

The co-extrusion technology of HOKASU Protect Cover (HPC) has made it possible to develop a diffuser that has simple light transmission and a long service life. Each diffuser is made of two materials:

- Polycarbonate. Used for resistance to external influences and high temperatures. Suitable for indoor and outdoor use;

- Acrylic. To prevent yellowing due to exposure to UV rays. Throughout its lifetime, which is more than 10 years, the luminaire maintains quality light without changing the color temperature.

HOKASU Heat Control (HHC) is a special polycarbonate that has 10 times the heat output of conventional untreated plastic. The main factor affecting the luminaire durability is good cooling of LED modules, which is very important in the design. Recall that the HOKASU linear luminaire is based on aircraft aluminum. The only element that does not transmit heat well is the diffuser. Based on these factors, we developed a polycarbonate using HHC technology, which allowed us to increase the heat transfer in the finished luminaire.

In the manufacture of diffusers patented German light-scattering polycarbonate granules are used.

The diffuser does not change color throughout its lifetime (more than 10 years).

There are two diffuser options to choose from:

- Color opal (75% light transmission). Coextrusion technology + UV protection on 2 sides «HEP – HOKASU protect cover»;

- Transparent polycarbonate with effect microprisms .